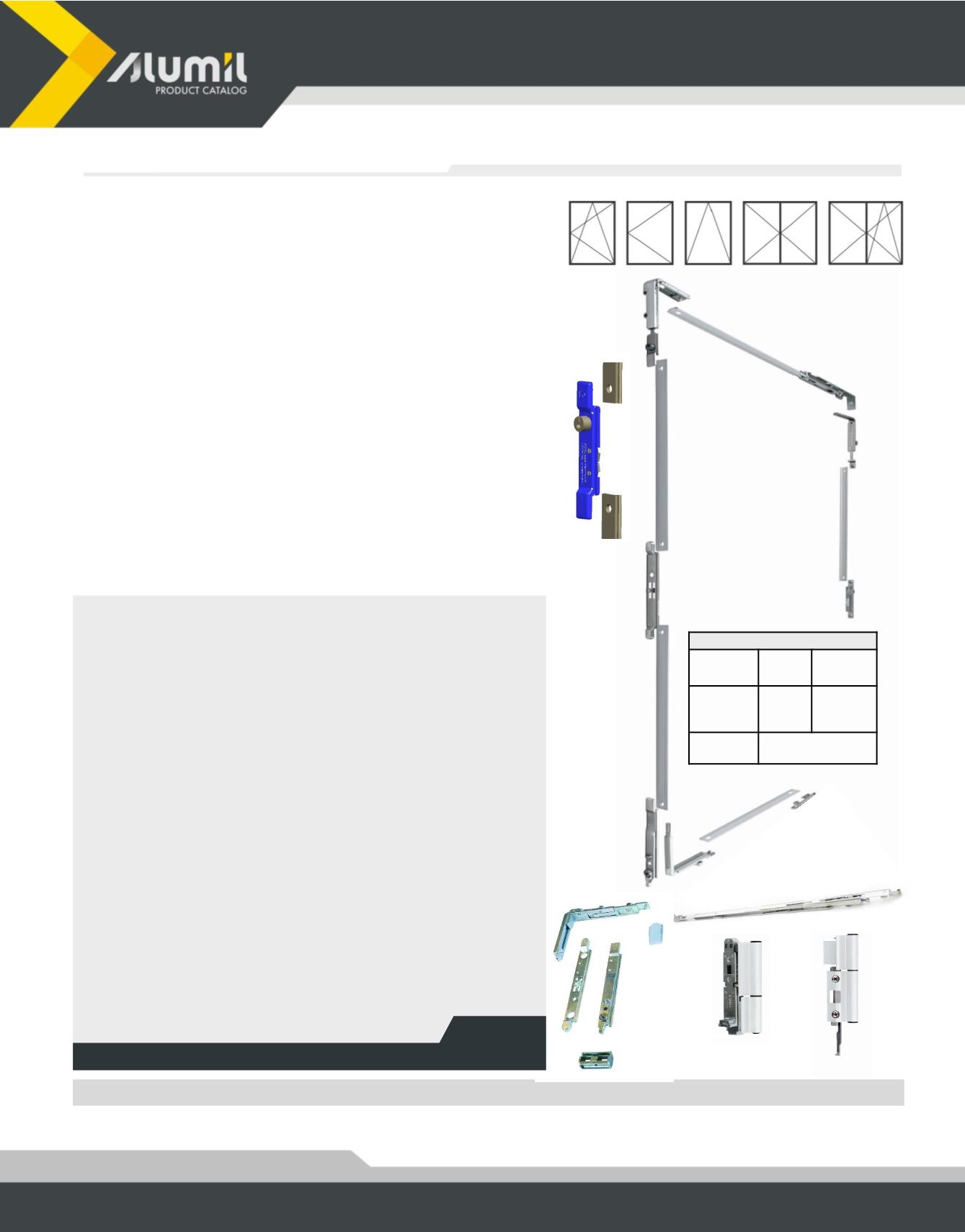

FUNCTION

Alumil branded Euro-groove hardware system for all Alumil 15/20 sash euro groove

profile systems

TECHNICAL FEATURES

•

Tilt/turn hardware system available in two versions: compatible with both the

Alumil cremone and the Alumil 7mm spindle handle

•

Mishandling device for both handle versions

•

All hardware components are suitable for left and right handed windows

•

Convenient 3D hardware adjustment

•

General gasket pressure adjustment on all eccentric locking cams using a 4mm

Allen key to achieve optimized pressure and tightness of the sash

•

All hinge parts completely clampable, enabling efficient installation with no

drilling necessary

•

The connecting-rod Ø6mm coupling-system simplifies hardware installation

•

The connecting-rod geometry is perfectly adapted to the 15/20 sash groove

•

Identical hardware aesthetics of top stay hinge and bottom pivot rest - all flush

with the sash overlap

•

Also available in Tilt-First version

•

Four different hardware locking options for the passive sash

•

Sash width from 355 to 1700mm

•

Sash height from 500 to 2800mm

•

For sash widths exceeding 1400mm an additional stay arm is required

•

Hardware load-bearing capacity tested up to 130kg sash weight

•

Alumil branded

Part numbers, descriptions and application ranges are depicted in the corresponding hardware catalogue and installation drawings.

CODES & DESCRIPTIONS

ALUMIL EURO GROOVE T/T MECHANISM

11

Adjustments

Corner hinge

± 1.0 mm

lateral

± 1.5 mm

height

Stay arm

± 3 mm

lateral

± 1 mm

gasket

pressure

Locking cams

± 1 mm

gasket pressure

MATERIALS

•

Hardware components from high-quality steel, Zamac die-casting and aluminium

alloys

•

Aluminium components are anodized or powder-coated

•

The steel components consist of stainless alloys

SURFACE COATING

•

White powder coated hinges RAL 9016

•

Black powder coated hinges RAL 9005

•

Anodised silver hinges in F1/EV1 surface-finish

•

Mill finish (non-treated) hinges for project-related coating

•

Zamac die-casting components are subjected to bichromating surface treatment

and an additional silver-coloured coating

CERTIFICATION

•

Alumil extended 10 Year Guarantee (standard 5 years)

•

Tilt/turn hardware durability testing: Grade 4 - 15,000 test cycles in accordance

with EN 13126-8:2006 (equivalent to 60,000 individual turn, tilt and lock

operations)

•

Corrosion resistance:

- Hardware set: Grade 4 - >240h salt-spray test [EN 13126-8:2006]

- Individual zinc die-cast component with bichromating treatment: Grade 5 -

>1,000h salt-spray test [EN 1670, EN 9227 based on EN 13126-1:2011]

•

In accordance with REACH regulation (1907/2006/EG) regarding SVHC substances

•

Tested in accordance with the requirements of the RAL-GZ 607/3:2009 Regulation

by the German RAL institute

•

DIN EN ISO 9001:2008