FUNCTION

Composite materials by Alumil for complete, tested and certified

systems

TECHNICAL FEATURES

•

Latest technology production processes

•

3D designing and 3D printing prototypes

•

Electronically controlled heating and cooling for top material quality

•

5 axis CNC machines for mold production

•

Excellent quality material and production ensures form retention

and UV resistance

•

All thermoplastic accessories are part of the official Alumil system

certification

•

Compression and Ageing tested between -10 and 100

ο

C

•

Individual accessory design and certification upon request

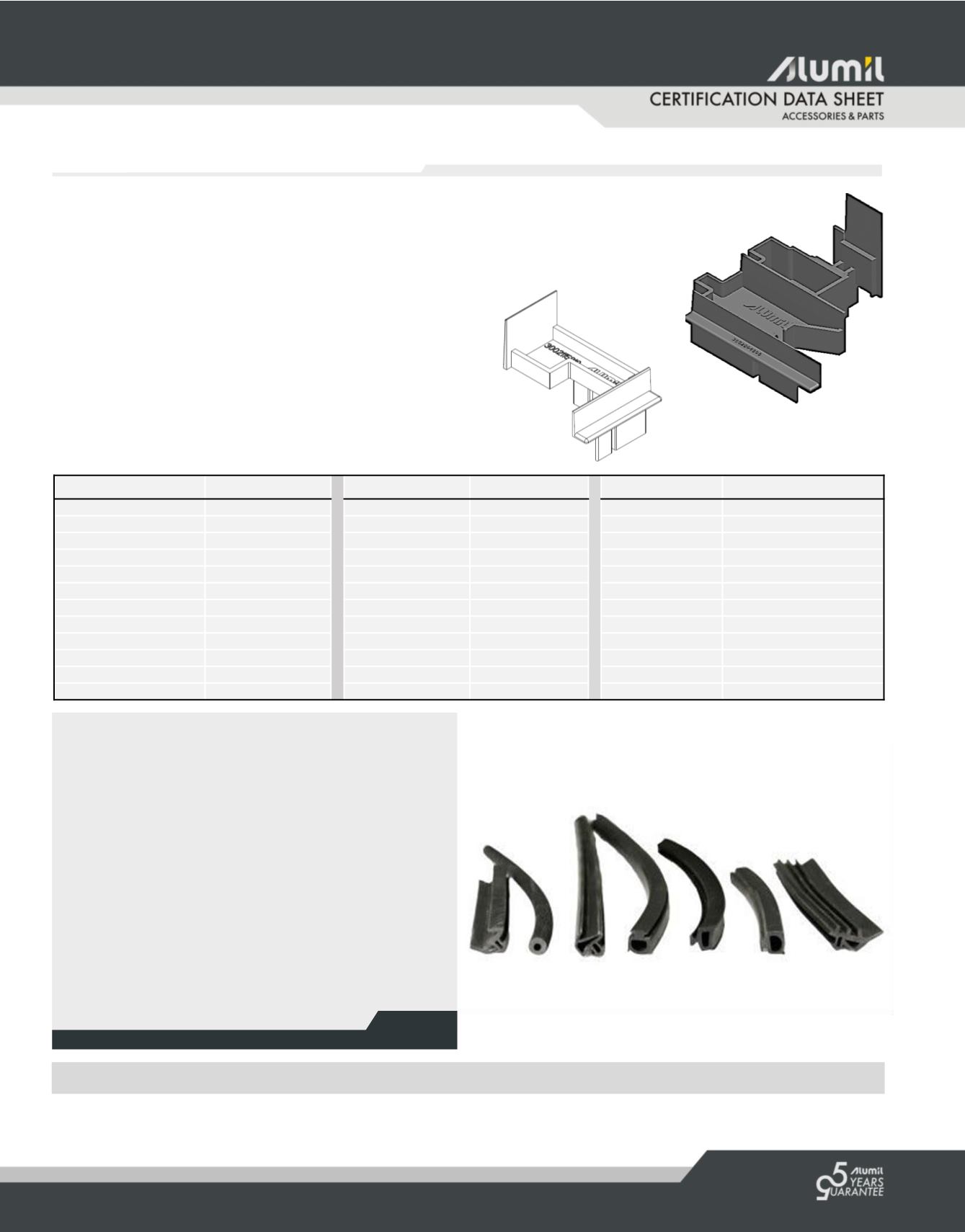

MATERIALS

•

Polyamide PA6 Glass reinforced

•

PVC

•

EPDM

SURFACE COATING

•

No surface coating applied

•

Color is part of material

•

Accessories may be coated with silicone for ease of application

CERTIFICATION

•

All materials fully certified based on ISO, EN standards

•

Tested for physical, mechanical, chemical, electrical and

flammability characteristics

•

ISO 9001:2008

•

Alumil 5 Year Guarantee

Codes to be specified upon request

Material

EPDM

Material

PVC - UV

Material

Polyamide

Color

Bk (Black)

Color

Bk (black)

Color

Bk (black)

Material Type

Ro/He Epdm

Material Type

PVC - UV

Material Type

PA6.6-GF25

Standard Ref.

DIN 7863

Specific Weight

ISO 1183: 1450

Viscosity

ISO 307: 150

Hardness

ASTM D 2240: 72 sh.

Vicat Point (5kg)

ISO 306: 78,5

Water Absorb.

ISO 62: 4

Specific Gravity

ASTM D 1817: 1.204 Hardness

ISO 868: 76,5

Moist Absorb.

ISO 62: 1.2

Tensile Strength

ASTM D 412c: 8,4

Tensile Strength

ISO 527: 30

Melting Temp.

ISO 3146: 240

Ultimate Elong.

ASTM D 412c: 280

Yield Point

ISO 527: 32

Melting Rate

ISO 3146: 20

Modulus 100%

ASTM D 412c: 4,4

Elongation at Break ISO 527: 100

Melting Extrus.

300c

Modulus 200%

ASTM D 412c: 7,1

Flexural Modulus

ISO 178: 2000

Stress at Break

ISO 527-2: 130

Tear Resistance

ASTM D 624b: 31

Impact Strength

ISO 180: 1100

Impact Strength

ISO 179/1eu: 60

Compression Set 100c ASTM D 395b: 29% Inflamability

UL94: V0

Compression Set -22c

ASTM D 395b: 43%

ALUMIL SYSTEM COMPOSITES

CODES & DESCRIPTIONS

56